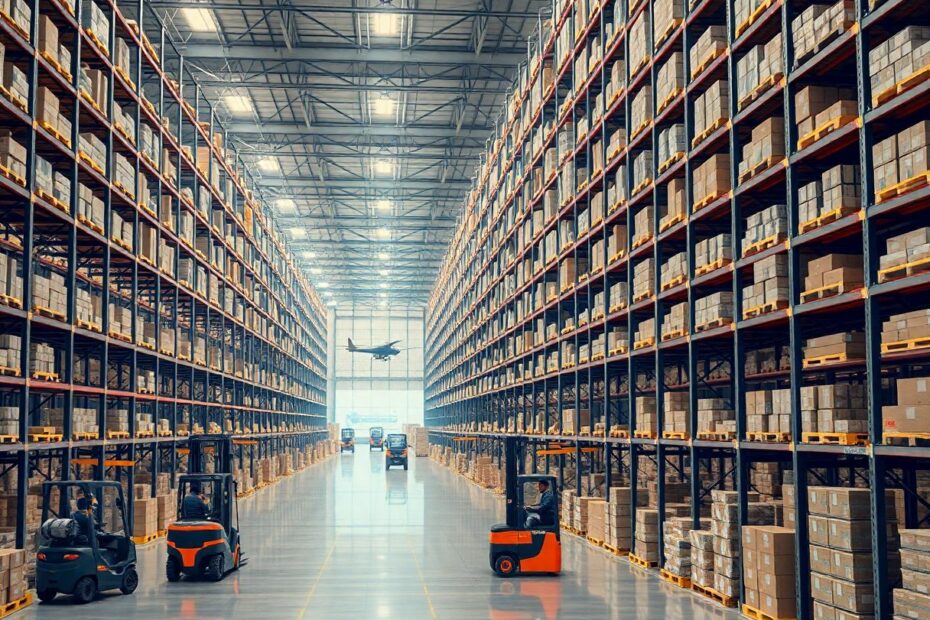

In today's lightning-fast global economy, the efficient storage and distribution of goods are paramount for businesses to succeed. At the heart of this intricate process lies warehousing – a critical component that keeps the gears of commerce turning smoothly. But what exactly is warehousing, and why has it become so indispensable? Let's embark on a comprehensive journey into the world of warehousing and explore its profound significance in the modern business landscape.

Defining Warehousing: More Than Just Storage

Warehousing is the systematic process of storing goods and materials in a dedicated facility for future use or distribution. However, it's far more complex than simply stacking boxes in a large building. Modern warehousing is a sophisticated operation that involves meticulous planning, organization, and management of inventory.

Key Aspects of Warehousing:

- Storage: Providing a safe and secure environment for goods

- Inventory Management: Tracking and controlling stock levels with precision

- Order Fulfillment: Efficiently picking, packing, and shipping products

- Receiving: Accepting and processing incoming shipments accurately

- Distribution: Coordinating the seamless movement of goods to their next destination

Warehousing plays a pivotal role in bridging the gap between production and consumption, ensuring that products are available when and where they're needed, thus maintaining the delicate balance of supply and demand.

The Evolution of Warehousing: From Simple Storage to High-Tech Hubs

The history of warehousing is a testament to human ingenuity and technological progress. Let's trace its fascinating evolution:

Ancient Warehouses (3000 BCE – 1800s):

- Began in ancient civilizations like Egypt and Rome

- Primarily used for grain storage and military supplies

- Simple structures with basic inventory methods

Industrial Revolution Warehouses (1800s – 1900s):

- Expanded with the growth of manufacturing and railroads

- Introduced steam-powered equipment for handling goods

- Developed more sophisticated inventory tracking systems

Modern Warehouses (1900s – 1980s):

- Saw the introduction of forklifts and pallets

- Implemented early computer systems for inventory management

- Began using conveyor belts for more efficient material handling

Automated Warehouses (1980s – 2000s):

- Integrated robotics and advanced computer systems

- Introduced automated storage and retrieval systems (AS/RS)

- Developed warehouse management systems (WMS) for real-time tracking

Smart Warehouses (2000s – Present):

- Utilize AI, IoT, and advanced analytics for predictive operations

- Implement drone technology for inventory counting

- Leverage augmented reality for enhanced picking accuracy

As we look towards 2025 and beyond, the trend is clearly moving towards "intelligent warehouses" that harness cutting-edge technologies to optimize operations, improve efficiency, and provide unprecedented visibility into the supply chain.

Types of Warehousing: Tailored Solutions for Diverse Needs

The world of warehousing is not monolithic. Different businesses have unique requirements, and various types of warehouses cater to these diverse needs:

1. Private Warehousing

- Owned and operated by a single company

- Offers complete control over operations and security

- Ideal for businesses with consistent, high-volume storage needs

- Examples: Amazon's fulfillment centers, Walmart's distribution centers

2. Public Warehousing

- Shared facility used by multiple businesses

- Cost-effective for smaller companies or those with fluctuating storage needs

- Offers flexibility and scalability

- Examples: CEVA Logistics, DHL Supply Chain

3. Contract Warehousing

- Long-term arrangement between a business and a third-party logistics provider

- Combines benefits of private and public warehousing

- Tailored services to meet specific business needs

- Examples: Kuehne + Nagel, DB Schenker

4. Bonded Warehousing

- Stores imported goods before customs duties are paid

- Helps in deferring tax payments

- Useful for businesses involved in international trade

- Examples: UPS Supply Chain Solutions, FedEx Trade Networks

5. Cold Storage Warehousing

- Specialized facilities for temperature-sensitive products

- Essential for food, pharmaceuticals, and chemicals industries

- Maintains product quality and extends shelf life

- Examples: Americold, Lineage Logistics

6. Cross-Docking Warehouses

- Designed for rapid transfer of goods from inbound to outbound transportation

- Minimizes storage time and handling

- Ideal for perishable goods or just-in-time inventory systems

- Examples: Walmart's cross-docking facilities, Target's flow centers

7. Fulfillment Centers

- Specialized warehouses for e-commerce order processing

- Focus on rapid order picking, packing, and shipping

- Often include value-added services like gift wrapping

- Examples: Amazon Fulfillment Centers, Shopify Fulfillment Network

The Crucial Role of Warehousing in Supply Chain Management

Warehousing is not just a static component of the supply chain; it's a dynamic force that influences every aspect of the logistics process. Here's how warehousing impacts supply chain management:

Buffer Against Demand Fluctuations:

- Warehouses help businesses maintain optimal stock levels to meet unexpected surges in demand.

- According to a study by the Warehousing Education and Research Council, companies that effectively use warehousing as a buffer can reduce stockouts by up to 30%.

Consolidation of Goods:

- They allow for the grouping of products from different suppliers, optimizing transportation and reducing costs.

- The National Association of Manufacturers reports that consolidation in warehousing can lead to a 15-25% reduction in transportation costs.

Value-Added Services:

- Many warehouses offer additional services like packaging, labeling, and light assembly.

- A report by Deloitte found that warehouses offering value-added services can increase their revenue by up to 20%.

Risk Mitigation:

- Proper warehousing helps protect goods from theft, damage, and environmental factors.

- The International Warehouse Logistics Association estimates that effective warehousing can reduce product damage rates by up to 80%.

Improved Customer Service:

- Strategically located warehouses can significantly reduce delivery times and improve customer satisfaction.

- A study by PwC found that 41% of consumers are willing to pay more for same-day delivery, highlighting the importance of efficient warehousing and distribution.

Inventory Optimization:

- Advanced warehouse management systems enable real-time inventory tracking and optimization.

- According to Gartner, companies using advanced inventory optimization techniques can reduce inventory levels by 10-30% while maintaining or improving service levels.

Data-Driven Decision Making:

- Modern warehouses generate vast amounts of data that can be analyzed to improve operations and inform business strategy.

- McKinsey reports that data-driven warehouses can reduce picking errors by up to 30% and increase productivity by 25-30%.

Warehousing Operations and Processes: The Heartbeat of Efficiency

Efficient warehousing relies on a series of well-coordinated operations, each critical to the smooth flow of goods:

1. Receiving

- Unloading incoming shipments with precision

- Inspecting goods for damage or discrepancies

- Updating inventory records in real-time

- Key Performance Indicator (KPI): Receiving accuracy rate (industry average: 99.5%)

2. Put-away

- Transferring goods to designated storage locations using optimal routes

- Organizing items for easy retrieval based on turnover rates

- Implementing cross-docking for fast-moving items

- KPI: Put-away cycle time (industry benchmark: 1-2 hours)

3. Storage

- Maintaining proper conditions for different types of goods (temperature, humidity, etc.)

- Implementing effective storage systems (e.g., pallet racking, automated storage and retrieval systems)

- Optimizing space utilization through slotting analysis

- KPI: Warehouse capacity utilization (target: 85-90%)

4. Order Picking

- Retrieving items for customer orders with maximum efficiency

- Utilizing advanced picking methods (e.g., zone picking, batch picking, voice-directed picking)

- Implementing pick-to-light or put-to-light systems for improved accuracy

- KPI: Order picking accuracy (industry best practice: 99.9%)

5. Packing and Shipping

- Preparing orders for shipment with appropriate packaging

- Selecting optimal shipping carriers based on cost and delivery time

- Generating and applying shipping labels and documentation

- KPI: On-time shipping rate (industry goal: 98-99%)

6. Returns Processing

- Receiving and inspecting returned items

- Determining appropriate disposition (restock, refurbish, or discard)

- Updating inventory and customer records accordingly

- KPI: Returns processing cycle time (target: 24-48 hours)

Warehousing Technologies and Innovations: Shaping the Future of Logistics

The warehousing industry is at the forefront of technological innovation, constantly evolving to meet the demands of modern commerce:

Warehouse Management Systems (WMS):

- Software that oversees all warehouse operations, from inventory tracking to order fulfillment.

- Market leaders include Manhattan Associates, Blue Yonder, and SAP.

- According to Gartner, the WMS market is expected to grow at a CAGR of 14% through 2025.

Automated Guided Vehicles (AGVs):

- Self-driving vehicles that transport goods within the warehouse, reducing labor costs and improving safety.

- Major players include Dematic, Swisslog, and Fetch Robotics.

- The AGV market is projected to reach $2.9 billion by 2026, growing at a CAGR of 9.3% (MarketsandMarkets).

Robotic Process Automation (RPA):

- Robots that perform repetitive tasks like sorting and packing, increasing speed and accuracy.

- Companies like Boston Dynamics and Locus Robotics are pioneering warehouse robotics.

- The warehouse robotics market is expected to grow from $4.7 billion in 2021 to $9.1 billion by 2026 (MarketsandMarkets).

Internet of Things (IoT):

- Sensors and connected devices that provide real-time data on inventory levels, equipment status, and environmental conditions.

- IoT in warehousing can lead to a 20-30% reduction in inventory carrying costs (Deloitte).

Artificial Intelligence (AI) and Machine Learning:

- Advanced algorithms that optimize inventory management, predict demand, and enhance decision-making.

- AI in supply chain and warehousing is expected to reach $10 billion in market value by 2025 (Tractica).

Augmented Reality (AR):

- Technology that assists workers in locating items and performing tasks more efficiently.

- Companies like DHL have reported productivity improvements of up to 25% using AR in picking processes.

Blockchain:

- Secure, transparent record-keeping that improves traceability and reduces fraud in the supply chain.

- The blockchain in supply chain market is expected to grow from $253 million in 2020 to $3,272 million by 2026 (MarketsandMarkets).

Drones:

- Used for inventory counting, surveillance, and even small-scale deliveries within warehouses.

- The warehouse drone market is projected to reach $29 billion by 2027 (Drone Industry Insights).

Despite technological advancements, warehousing still faces several challenges that require innovative solutions:

Space Optimization:

- Maximizing storage capacity while maintaining accessibility

- Solution: Implementing vertical storage systems and using AI for optimal space utilization

Labor Shortages:

- Finding and retaining skilled warehouse workers

- Solution: Investing in automation and providing comprehensive training programs

Inventory Accuracy:

- Maintaining precise stock counts in large, dynamic environments

- Solution: Utilizing RFID technology and cycle counting methods

Sustainability:

- Reducing environmental impact through energy-efficient practices and waste reduction

- Solution: Adopting green building standards and implementing recycling programs

Cybersecurity:

- Protecting sensitive data and systems from digital threats

- Solution: Implementing robust cybersecurity measures and regular staff training

Adaptability:

- Quickly adjusting to changing market demands and new technologies

- Solution: Developing flexible warehouse designs and investing in scalable technologies

Last-Mile Delivery:

- Managing the final leg of delivery in urban areas

- Solution: Establishing micro-fulfillment centers and partnering with local delivery services

Reverse Logistics:

- Efficiently handling returns and exchanges

- Solution: Implementing dedicated returns processing areas and streamlined RMA processes

The Future of Warehousing: Trends Shaping Tomorrow's Logistics

As we peer into the future, several trends are poised to revolutionize the warehousing industry:

Hyper-Automation:

- Integration of AI, machine learning, and robotics to create fully automated warehouses

- Prediction: By 2030, 30% of warehouses will be fully automated (Gartner)

Sustainable Warehousing:

- Greater focus on eco-friendly operations, including energy-efficient buildings and green logistics

- Goal: Net-zero carbon emissions in warehousing by 2050 (World Green Building Council)

Urban Micro-Fulfillment:

- Rise of smaller, strategically located warehouses in city centers to facilitate faster deliveries

- Forecast: The micro-fulfillment market is expected to reach $10 billion by 2026 (Interact Analysis)

Omnichannel Integration:

- Warehouses adapting to serve both online and offline retail channels seamlessly

- Statistic: 73% of customers use multiple channels during their shopping journey (Harvard Business Review)

Predictive Analytics:

- Leveraging big data and AI to forecast demand and optimize inventory levels

- Impact: Up to 50% reduction in inventory costs through advanced analytics (McKinsey)

Collaborative Robots (Cobots):

- Integration of robots that work alongside human employees, enhancing productivity and safety

- Projection: The cobot market in logistics is expected to grow at a CAGR of 45% through 2026 (ABI Research)

Blockchain Integration:

- Improved transparency and traceability throughout the supply chain

- Adoption: 60% of CIOs expect to adopt blockchain technology in their supply chains by 2025 (Gartner)

5G and Edge Computing:

- Ultra-fast, low-latency networks enabling real-time data processing and decision-making

- Forecast: 5G IoT connections in warehousing to grow at a CAGR of 464% between 2019 and 2025 (Ericsson)

Conclusion: The Indispensable Role of Warehousing in Modern Business

Warehousing has evolved from a simple storage solution to a complex, technology-driven ecosystem that forms the backbone of global commerce. As businesses continue to adapt to changing consumer demands and technological advancements, the importance of efficient warehousing only grows more pronounced.

From ensuring product availability to optimizing supply chains, warehousing touches every aspect of modern commerce. Whether you're a small e-commerce startup or a multinational corporation, understanding and leveraging the power of warehousing is essential for success in today's competitive marketplace.

As we move forward, the warehousing industry will continue to evolve, driven by innovation and the ever-increasing demand for faster, more efficient logistics. By staying informed about these developments and embracing new technologies, businesses can ensure they remain agile, competitive, and ready to meet the challenges of tomorrow's market.

In the end, effective warehousing isn't just about storing products—it's about creating value, enhancing customer satisfaction, and driving business growth in an increasingly interconnected world. As we stand on the cusp of a new era in logistics, one thing is clear: warehousing will continue to be the cornerstone upon which successful supply chains are built.