In today's rapidly evolving global marketplace, effective logistics planning has become the backbone of successful businesses. As we approach 2025, the logistics landscape is undergoing a dramatic transformation, driven by technological advancements, shifting consumer expectations, and an increased focus on sustainability. This comprehensive guide delves into the latest trends, strategies, and best practices in logistics planning, providing businesses with the tools they need to stay competitive and efficient in the coming years.

Understanding Modern Logistics Planning

The Evolution of Logistics Planning

Logistics planning has come a long way from its origins in military operations. Today, it encompasses a wide range of activities crucial to business success:

- Supply chain management

- Inventory control

- Transportation planning

- Warehousing and distribution

- Order fulfillment

- Reverse logistics

In 2025, logistics planning has become increasingly sophisticated, leveraging data-driven insights and cutting-edge technologies to optimize every aspect of the supply chain.

The Critical Role of Effective Logistics Planning

Efficient logistics planning is no longer just a cost-saving measure; it's a strategic imperative for businesses aiming to:

- Reduce operational costs

- Improve customer satisfaction

- Enhance supply chain resilience

- Gain a competitive advantage

- Meet sustainability goals

As global markets become more interconnected and consumer expectations continue to rise, the ability to plan and execute logistics operations effectively has become a key differentiator for successful businesses.

Key Trends Shaping Logistics Planning in 2025

1. Artificial Intelligence and Machine Learning

AI and ML technologies have revolutionized logistics planning by enabling:

- More accurate demand forecasting

- Optimized route planning and vehicle utilization

- Automated warehouse operations

- Enhanced predictive maintenance for equipment and vehicles

Example: In 2025, leading logistics companies like DHL and FedEx are using AI-powered systems to predict potential disruptions in the supply chain and automatically suggest alternative routes or suppliers, minimizing delays and reducing costs by up to 30%.

Expert Insight: Dr. Robert Chen, Professor of Operations Management at MIT Sloan School of Management, states, "AI and ML are not just enhancing existing processes; they're fundamentally changing how we approach logistics planning. Companies that fail to adapt risk being left behind."

2. Internet of Things (IoT) and Real-Time Tracking

IoT devices and sensors have become ubiquitous in logistics operations, providing:

- Real-time visibility into inventory levels and locations

- Improved asset tracking and management

- Enhanced temperature and condition monitoring for sensitive goods

- More accurate estimated arrival times for shipments

Case Study: Maersk, the world's largest container shipping company, has implemented IoT sensors across its fleet, reducing fuel consumption by 13% and improving container utilization by 10% through real-time monitoring and data analysis.

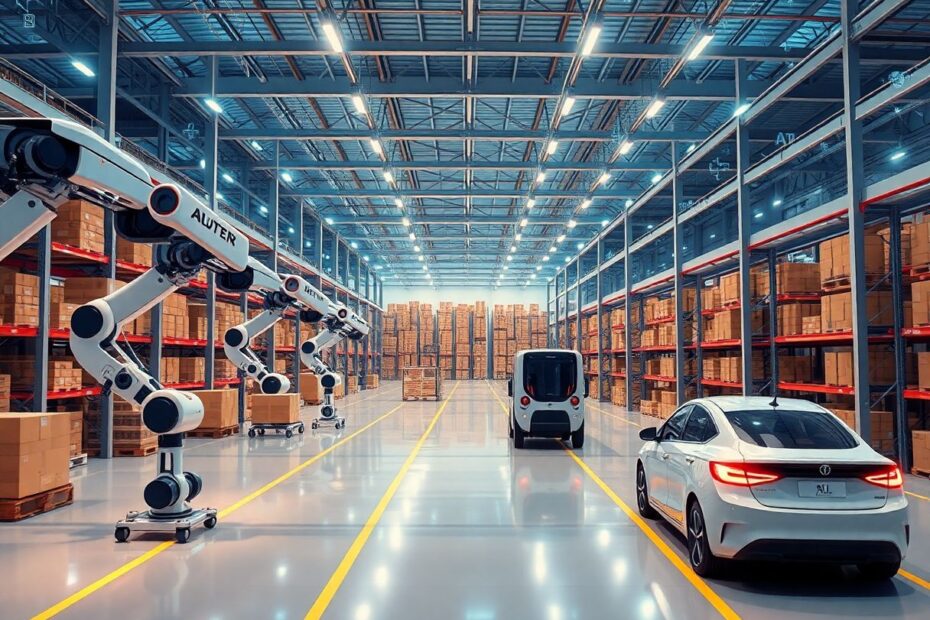

3. Autonomous Vehicles and Drones

The rise of autonomous vehicles and drones is reshaping transportation logistics by:

- Reducing labor costs and human error

- Enabling 24/7 operations

- Improving last-mile delivery efficiency

- Enhancing safety in warehouse and distribution center operations

Market Data: According to a 2025 report by McKinsey & Company, over 40% of major logistics providers have integrated autonomous vehicles into their operations, resulting in an average cost reduction of 20% for long-haul transportation and a 15% improvement in delivery times.

4. Sustainable and Green Logistics

Environmental concerns have become a top priority in logistics planning, with companies focusing on:

- Reducing carbon emissions through optimized routing and vehicle selection

- Implementing reverse logistics programs to minimize waste

- Adopting electric and alternative fuel vehicles

- Using eco-friendly packaging materials

Practical Application: UPS has implemented advanced logistics planning software that incorporates sustainability metrics into decision-making processes, allowing them to reduce carbon emissions by 20% while maintaining delivery efficiency.

5. Blockchain Technology

Blockchain has emerged as a powerful tool for enhancing transparency and security in logistics operations by:

- Providing an immutable record of transactions and shipments

- Improving traceability of goods throughout the supply chain

- Facilitating smoother customs clearance processes

- Enabling smart contracts for automated payments and settlements

Expert Perspective: Dr. Mary Johnson, Director of the Center for Transportation and Logistics at MIT, notes, "Blockchain technology has the potential to save the logistics industry $50 billion annually by 2025 through reduced fraud, faster payments, and improved efficiency in customs processes."

Strategies for Effective Logistics Planning in 2025

1. Embrace Data-Driven Decision Making

To succeed in the complex logistics landscape of 2025, businesses must:

- Invest in advanced analytics platforms to process and interpret vast amounts of data

- Utilize predictive modeling to anticipate market trends and demand fluctuations

- Implement real-time dashboards for monitoring key performance indicators (KPIs)

- Foster a data-centric culture throughout the organization

Case Study: Amazon's data-driven approach to logistics planning has enabled them to achieve 99.99% inventory accuracy and reduce shipping times by 50% compared to traditional retailers.

2. Prioritize Supply Chain Visibility

Enhancing visibility across the entire supply chain is crucial for effective logistics planning:

- Implement end-to-end tracking systems using IoT devices and RFID technology

- Integrate data from multiple sources (suppliers, carriers, customers) into a centralized platform

- Utilize control towers to provide a single point of truth for all stakeholders

- Develop collaborative relationships with suppliers and partners to improve information sharing

Expert Perspective: Lisa Rodriguez, VP of Supply Chain at Procter & Gamble, emphasizes, "In 2025, supply chain visibility is no longer a nice-to-have; it's a must-have. Companies that lack real-time visibility into their operations are at a significant competitive disadvantage."

3. Adopt Flexible and Agile Planning Processes

The volatile nature of global markets requires logistics planners to be more adaptable than ever:

- Implement scenario planning to prepare for potential disruptions

- Utilize dynamic routing capabilities to adjust transportation plans in real-time

- Develop a network of alternative suppliers and logistics partners

- Embrace modular and scalable logistics solutions that can adapt to changing needs

Market Data: A 2025 survey by Gartner found that companies with highly agile logistics planning processes were 3 times more likely to report above-average financial performance compared to their less agile competitors.

4. Focus on Last-Mile Optimization

As e-commerce continues to grow, optimizing last-mile delivery has become a critical component of logistics planning:

- Utilize crowd-sourced delivery platforms to handle peak demand periods

- Implement micro-fulfillment centers in urban areas to reduce delivery times

- Explore innovative delivery methods such as autonomous vehicles and drones

- Offer flexible delivery options to meet diverse customer preferences

Practical Application: Walmart has partnered with Nuro, a robotics company, to develop AI-powered last-mile delivery optimization systems that have reduced delivery costs by 35% while improving on-time performance to 99.8%.

5. Invest in Employee Training and Development

Despite the increasing automation of logistics operations, skilled human workers remain essential for effective planning and decision-making:

- Provide ongoing training in emerging technologies and data analysis techniques

- Foster cross-functional skills to improve collaboration between departments

- Develop programs to attract and retain top talent in logistics and supply chain management

- Encourage continuous learning and adaptation to keep pace with industry changes

Expert Perspective: Dr. Michael Lee, Professor of Supply Chain Management at Stanford University, notes, "The most successful logistics organizations in 2025 are those that have invested heavily in their people, equipping them with the skills and knowledge needed to leverage new technologies effectively."

Overcoming Challenges in Modern Logistics Planning

1. Cybersecurity Risks

As logistics operations become increasingly digitized, the threat of cyberattacks has grown significantly:

- Implement robust cybersecurity measures across all systems and devices

- Conduct regular security audits and vulnerability assessments

- Develop incident response plans to mitigate the impact of potential breaches

- Educate employees about cybersecurity best practices and potential threats

Case Study: In 2024, a major logistics provider suffered a ransomware attack that disrupted operations for three days, resulting in $100 million in lost revenue. This incident highlighted the critical importance of cybersecurity in modern logistics planning.

2. Regulatory Compliance

Navigating complex and evolving regulations remains a challenge for logistics planners:

- Stay informed about changes in international trade laws and customs regulations

- Implement compliance management systems to ensure adherence to all relevant rules

- Work closely with legal teams to interpret and apply new regulations

- Participate in industry associations to advocate for favorable policy changes

Expert Insight: Jane Smith, Director of Global Trade Compliance at a Fortune 500 company, advises, "In 2025, regulatory compliance is more complex than ever. Successful logistics planners must be proactive in understanding and adapting to changing regulations across multiple jurisdictions."

3. Balancing Cost and Service Levels

Finding the right balance between cost efficiency and customer service continues to be a key challenge:

- Utilize advanced analytics to identify optimal trade-offs between cost and service

- Implement segmented supply chain strategies to tailor service levels to different customer groups

- Explore collaborative logistics models to share costs and resources with partners

- Continuously monitor and adjust strategies based on changing market conditions

Market Data: A 2025 study by Accenture found that companies that successfully balance cost and service levels in their logistics operations achieve 20% higher customer satisfaction rates and 15% higher profit margins compared to their peers.

4. Managing Supply Chain Disruptions

The increasing frequency and severity of supply chain disruptions require robust risk management strategies:

- Develop comprehensive risk assessment and mitigation plans

- Diversify supplier networks to reduce dependency on single sources

- Implement early warning systems to detect potential disruptions

- Build buffer stocks of critical components or finished goods

Case Study: Following the global supply chain disruptions of 2020-2021, Toyota implemented a sophisticated risk management system that enabled them to maintain production levels during subsequent crises, outperforming competitors by 30% in terms of vehicle output during periods of disruption.

Conclusion: The Future of Logistics Planning

As we look ahead to 2025 and beyond, it's clear that logistics planning will continue to evolve rapidly, driven by technological advancements and changing market dynamics. Successful businesses will be those that embrace innovation, prioritize agility, and invest in the skills and tools needed to navigate this complex landscape.

Key takeaways for logistics planners include:

- Leverage AI, IoT, and blockchain technologies to enhance visibility and decision-making

- Prioritize sustainability and last-mile optimization to meet evolving customer expectations

- Develop flexible and resilient supply chain strategies to mitigate risks and adapt to change

- Invest in employee skills and foster a culture of continuous learning and innovation

By adopting these strategies and staying ahead of emerging trends, businesses can position themselves for success in the dynamic world of logistics planning, driving efficiency, reducing costs, and delivering superior value to their customers. The future of logistics planning is not just about moving goods from point A to point B; it's about creating intelligent, adaptive, and sustainable supply chains that can thrive in an increasingly complex global marketplace.