In today's rapidly evolving business landscape, efficiency and speed are paramount. Cross dock warehousing has emerged as a game-changing strategy in logistics, transforming how companies manage their supply chains. This comprehensive guide delves into the world of cross docking, exploring its intricacies, benefits, challenges, and best practices. Whether you're a seasoned logistics professional or new to the concept, this article will equip you with the knowledge to leverage cross docking for your business success.

Understanding Cross Dock Warehousing

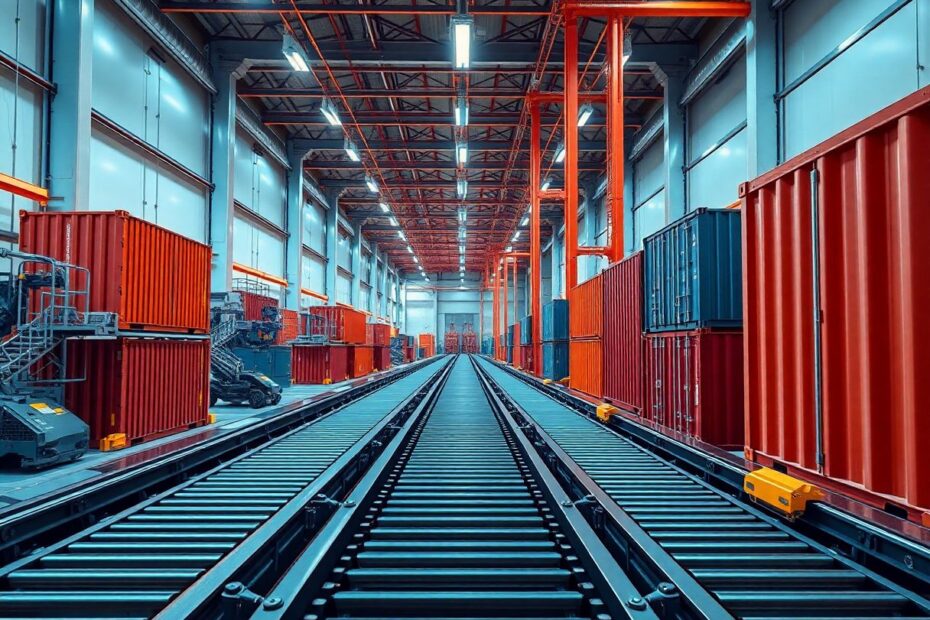

Cross dock warehousing is a logistics approach that minimizes storage time by transferring incoming goods directly to outbound vehicles. Unlike traditional warehousing, where products may sit on shelves for extended periods, cross docking aims to keep inventory in constant motion through the supply chain.

The Fundamentals of Cross Docking

At its core, cross docking is about speed and efficiency. The process typically unfolds as follows:

- Inbound trucks arrive at the cross dock facility

- Goods are unloaded and sorted

- Products are immediately transferred to outbound vehicles

- Outbound trucks depart for their final destinations

This streamlined process usually occurs within 24 hours or less, dramatically reducing storage time and associated costs. According to a study by the International Journal of Logistics Research and Applications, cross docking can reduce inventory holding costs by up to 70% compared to traditional warehousing methods.

Types of Cross Docking

Cross docking operations generally fall into two main categories:

Pre-distribution Cross Docking: In this model, goods are sorted and reconfigured before being sent out. This approach is ideal for combining products from multiple suppliers into customized shipments. For example, a retailer might use pre-distribution cross docking to create store-specific pallets containing a mix of products from various manufacturers.

Post-distribution Cross Docking: This method involves transferring products directly from inbound to outbound vehicles without additional sorting. It's particularly effective for time-sensitive deliveries to predetermined locations. A prime example is the distribution of perishable goods, where speed is crucial to maintain product freshness.

The Compelling Benefits of Cross Dock Warehousing

Cross docking offers numerous advantages for businesses looking to optimize their supply chains:

1. Reduced Storage Costs

By minimizing the time products spend in storage, companies can significantly cut warehouse expenses. A report by the Council of Supply Chain Management Professionals suggests that implementing cross docking can reduce warehousing costs by up to 50%.

2. Faster Delivery Times

Direct transfer from inbound to outbound vehicles accelerates the entire shipping process. This speed is particularly crucial in industries where time-to-market is a competitive advantage. For instance, fashion retailers using cross docking can respond more quickly to emerging trends, getting new styles into stores faster than competitors using traditional warehousing methods.

3. Improved Inventory Management

Cross docking reduces the risk of overstocking and product obsolescence. A study published in the International Journal of Production Economics found that companies implementing cross docking experienced a 25% reduction in inventory levels on average.

4. Enhanced Supply Chain Visibility

Real-time tracking of goods as they move through the cross dock facility improves overall supply chain transparency. This visibility allows for better decision-making and quicker responses to potential disruptions.

5. Lower Labor Costs

With less need for picking, packing, and long-term storage, labor requirements are reduced. The Aberdeen Group reports that companies using cross docking see an average reduction in labor costs of 20-30%.

6. Decreased Product Handling

Fewer touch points mean less risk of damage and loss. According to the Warehouse Education and Research Council, cross docking can reduce product damage by up to 60% compared to traditional warehousing methods.

While the benefits are compelling, cross docking isn't without its challenges:

1. Coordination Complexity

Successful cross docking requires precise timing and coordination between suppliers, transporters, and recipients. Any delays or miscommunications can disrupt the entire process.

2. Technology Requirements

Advanced software and hardware are necessary to manage the rapid flow of goods efficiently. This includes robust Warehouse Management Systems (WMS), Transportation Management Systems (TMS), and real-time tracking technologies.

3. Limited Product Suitability

Not all products are ideal for cross docking. Items with special handling requirements or low turnover may not be suitable. Typically, cross docking works best for high-volume, fast-moving goods with predictable demand.

4. Potential for Errors

The fast-paced nature of cross docking can lead to mistakes if processes aren't well-defined and monitored. Implementing rigorous quality control measures is essential to mitigate this risk.

5. Initial Setup Costs

Implementing a cross docking system may require significant upfront investment in facilities and technology. However, the long-term cost savings often outweigh these initial expenses.

Implementing a Successful Cross Dock Operation

Creating an effective cross dock operation involves several key steps:

1. Facility Design

The layout of a cross dock warehouse is crucial. Key elements include:

- Sufficient dock doors for simultaneous loading and unloading

- Ample staging areas for temporary product placement

- Efficient conveyor systems or material handling equipment

- Clear traffic flow patterns for forklifts and other vehicles

A well-designed cross dock facility can handle up to 100 inbound and outbound shipments per day, according to a report by the Material Handling Industry of America.

2. Technology Integration

Implementing the right technology is essential for smooth operations:

- Warehouse Management Systems (WMS) for real-time inventory tracking

- Transportation Management Systems (TMS) for coordinating inbound and outbound shipments

- Barcode scanners and RFID technology for accurate product identification

- Advanced analytics tools for performance monitoring and optimization

A study by Gartner found that companies implementing these technologies in their cross docking operations saw an average improvement in order accuracy of 99.5%.

3. Process Development

Establishing clear, standardized processes is critical:

- Define roles and responsibilities for all team members

- Create detailed workflows for receiving, sorting, and shipping

- Implement quality control measures at key points in the process

- Develop contingency plans for handling unexpected issues

4. Staff Training

Ensure your team is well-prepared:

- Provide comprehensive training on cross docking principles and best practices

- Offer hands-on experience with all relevant technology and equipment

- Emphasize the importance of accuracy and efficiency in all tasks

- Encourage continuous learning and process improvement

Best Practices for Cross Dock Warehousing

To maximize the benefits of cross docking, consider these best practices:

Prioritize Communication: Maintain open lines of communication with suppliers, carriers, and customers to ensure smooth coordination.

Leverage Data Analytics: Use advanced analytics to identify trends, optimize processes, and predict potential issues. Companies that effectively use data analytics in their cross docking operations have reported up to 30% improvement in operational efficiency, according to a study by McKinsey & Company.

Implement Rigorous Quality Control: Develop strict quality checks to minimize errors and ensure customer satisfaction. This includes regular audits and performance reviews.

Focus on Continuous Improvement: Regularly review and refine your cross docking processes to increase efficiency over time. Implement Kaizen principles to encourage ongoing, incremental improvements.

Invest in Automation: Where possible, automate repetitive tasks to improve speed and accuracy. Automated guided vehicles (AGVs) and robotic sorting systems can significantly enhance cross docking efficiency.

Maintain Flexibility: Be prepared to adapt your cross docking strategy as business needs and market conditions change. This might involve adjusting schedules, reconfiguring facility layouts, or adopting new technologies.

Real-World Applications of Cross Docking

Cross docking has found success across various industries:

Retail

Major retailers like Walmart have long used cross docking to keep stores stocked with fresh inventory. By rapidly moving products from suppliers to retail locations, they can respond quickly to changing consumer demands. Walmart attributes 85% of its sales to cross docking operations, according to a report by Supply Chain Dive.

Automotive

Car manufacturers use cross docking to manage the just-in-time delivery of parts to assembly lines. This reduces storage costs and ensures that production can continue without interruption. Toyota, a pioneer in just-in-time manufacturing, extensively uses cross docking in its global supply chain.

E-commerce

Online retailers leverage cross docking to speed up order fulfillment and reduce shipping times. This is particularly crucial for meeting customer expectations in the age of same-day and next-day delivery. Amazon, for instance, uses cross docking in its fulfillment centers to achieve rapid delivery times for Prime customers.

Food and Beverage

Perishable goods benefit greatly from cross docking. Companies can quickly move fresh produce, dairy, and other time-sensitive items from farms to stores, minimizing spoilage and maximizing shelf life. Kroger, one of the largest supermarket chains in the US, uses cross docking to manage its fresh produce supply chain, reducing waste by up to 25%.

The Future of Cross Dock Warehousing

As technology continues to evolve, the future of cross docking looks bright:

AI and Machine Learning: Advanced algorithms will optimize product flow and predict potential bottlenecks. AI-powered demand forecasting could improve cross docking efficiency by up to 50%, according to a report by Deloitte.

Internet of Things (IoT): Connected devices will provide real-time tracking and monitoring of goods throughout the cross docking process. The IoT market in logistics is expected to reach $100 billion by 2025, with cross docking being a key application area.

Robotics and Automation: Automated guided vehicles (AGVs) and robotic sorting systems will increase speed and accuracy. The warehouse robotics market is projected to grow at a CAGR of 14% from 2021 to 2026, driven in part by cross docking applications.

Blockchain Technology: Improved traceability and security of shipments will enhance supply chain transparency. Blockchain could reduce supply chain barriers in cross docking operations by up to 70%, according to a study by the World Economic Forum.

Is Cross Docking Right for Your Business?

While cross docking offers significant benefits, it's not suitable for every business. Consider these factors when deciding if cross docking is right for you:

- Product Characteristics: Ideal for high-volume, fast-moving goods with predictable demand.

- Supply Chain Complexity: Works best with well-coordinated supply chains and reliable partners.

- Technology Readiness: Requires robust IT infrastructure and willingness to invest in new systems.

- Business Goals: Aligns well with strategies focused on speed, efficiency, and cost reduction.

Conclusion: Embracing the Cross Docking Revolution

Cross dock warehousing represents a paradigm shift in logistics management. By prioritizing speed and efficiency, businesses can dramatically improve their supply chain performance, reduce costs, and enhance customer satisfaction. While implementing a cross docking system requires careful planning and investment, the potential rewards are substantial.

As we move into an increasingly fast-paced, digitally-driven future, cross docking will likely play an even more crucial role in supply chain management. Companies that embrace this innovative approach now will be well-positioned to thrive in the competitive landscape of tomorrow.

Whether you're considering implementing cross docking for the first time or looking to optimize your existing operations, remember that success lies in careful planning, robust technology, and a commitment to continuous improvement. By mastering the art and science of cross dock warehousing, you can unlock new levels of efficiency and drive your business forward in the exciting world of modern logistics.

As the logistics industry continues to evolve, cross docking stands out as a powerful tool for companies seeking to streamline their operations and stay ahead of the competition. With the right approach and a willingness to innovate, businesses of all sizes can harness the power of cross docking to build more responsive, efficient, and customer-centric supply chains.