In the rapidly evolving world of e-commerce, the ability to quickly and efficiently fulfill customer orders has become a critical competitive advantage. As we look ahead to 2025 and beyond, understanding and optimizing your order fulfillment cycle time (OFCT) is more crucial than ever for business success and customer satisfaction. This comprehensive guide will explore the ins and outs of OFCT, its far-reaching impact on your business, and cutting-edge strategies to improve it.

What is Order Fulfillment Cycle Time?

Order fulfillment cycle time refers to the total duration from when a customer places an order to when they receive it. This critical metric encompasses several key stages:

- Order processing

- Inventory sourcing

- Picking and packing

- Shipping

- Delivery to the customer

In an era where customers expect near-instant gratification, minimizing your OFCT can give you a significant edge over competitors. According to a recent study by McKinsey, 30% of consumers say they would pay extra for same-day delivery, highlighting the growing importance of speed in e-commerce.

The Formula for Calculating OFCT

To calculate your order fulfillment cycle time, use this simple formula:

OFCT = Sourcing Time + Production Time + Delivery Time

- Sourcing Time: The time taken to gather materials or products after an order is placed.

- Production Time: The duration for retrieving, inspecting, and packaging the product.

- Delivery Time: The period from when the package leaves your facility to when it reaches the customer.

It's crucial to track each of these components separately to identify bottlenecks and areas for improvement in your fulfillment process.

Why OFCT Matters: The Business Impact

Customer Satisfaction and Loyalty

In 2025, customer expectations for quick delivery have reached new heights. A study by Deloitte found that 87% of consumers consider shipping speed a key factor in their decision to shop with an e-commerce brand again. A shorter OFCT directly translates to higher customer satisfaction and increased loyalty.

Furthermore, research from the Harvard Business Review shows that customers who have a positive experience are likely to spend 140% more compared to those who have a negative experience. By optimizing your OFCT, you're not just meeting expectations – you're creating brand advocates.

Competitive Advantage

In a crowded marketplace, your OFCT can set you apart. Brands that consistently deliver faster than their competitors see a 25% increase in customer retention rates, according to a report by Bain & Company. This advantage is particularly crucial in industries with high competition and low product differentiation.

Operational Efficiency

Reducing your OFCT often leads to improvements across your entire operation. Companies that optimize their fulfillment processes report an average 30% reduction in operational costs, as found in a survey by Supply Chain Dive. This efficiency gain comes from:

- Reduced labor costs

- Lower inventory holding costs

- Fewer errors and returns

- Better utilization of warehouse space

Financial Performance

Faster fulfillment means quicker inventory turnover and improved cash flow. Businesses with optimized OFCTs see an average 15% increase in profit margins, according to data from the Aberdeen Group. This improvement stems from:

- Increased sales due to higher customer satisfaction

- Reduced costs from operational efficiencies

- Lower inventory carrying costs

- Fewer markdowns on slow-moving stock

Factors Affecting Order Fulfillment Cycle Time

1. Inventory Management

Effective inventory management is the foundation of a quick OFCT. Implementing advanced inventory forecasting tools can reduce stockouts by up to 40%, as reported by Gartner. Key strategies include:

- Real-time inventory tracking

- Demand forecasting using AI and machine learning

- Safety stock optimization

- Just-in-time inventory management

2. Warehouse Organization

A well-organized warehouse can cut picking times by 50%, according to a study by the Warehousing Education and Research Council. Consider implementing:

- AI-driven layout optimization

- Zone picking strategies

- Voice-directed picking systems

- Robotic assistance for repetitive tasks

3. Technology Integration

By 2025, 95% of top-performing e-commerce businesses will have fully integrated their order management, warehouse management, and shipping systems, as predicted by Forrester Research. This integration allows for:

- Real-time visibility across the supply chain

- Automated decision-making for optimal fulfillment routes

- Seamless communication between systems, reducing errors and delays

4. Shipping Partners

Choosing the right shipping partners is crucial. Look for carriers with a track record of 98% on-time delivery rates and seamless integration with your systems. According to a report by Convey, 98% of shoppers say shipping impacts their brand loyalty, making this a critical factor in your OFCT strategy.

5. Order Processing Automation

Automated order processing can reduce errors by 90% and cut processing times by 75%, as found in a study by Zebra Technologies. Key areas for automation include:

- Order validation and fraud detection

- Payment processing

- Order routing to the optimal fulfillment center

- Automatic generation of picking lists and shipping labels

Strategies to Improve Order Fulfillment Cycle Time

1. Implement Advanced Inventory Management Systems

Utilize AI-powered inventory management systems that can predict demand with 95% accuracy, ensuring you always have the right stock levels. These systems can:

- Analyze historical data, market trends, and external factors (like weather or events)

- Automatically adjust stock levels based on real-time data

- Identify slow-moving inventory for potential markdowns or redistribution

2. Optimize Warehouse Layout and Processes

Employ data analytics to continually refine your warehouse layout. Companies using this approach report a 40% increase in picking efficiency, according to a study by DHL. Key strategies include:

- Heat mapping to identify high-velocity items and place them in easily accessible locations

- Implementing cross-docking for fast-moving items

- Using slotting optimization software to determine the best product placement

3. Leverage Multi-Node Fulfillment Networks

Distribute your inventory across multiple fulfillment centers to reduce shipping distances. This strategy can cut delivery times by up to 50% for most customers, as reported by Amazon. Benefits include:

- Reduced shipping costs

- Faster delivery times

- Improved resilience against disruptions in specific regions

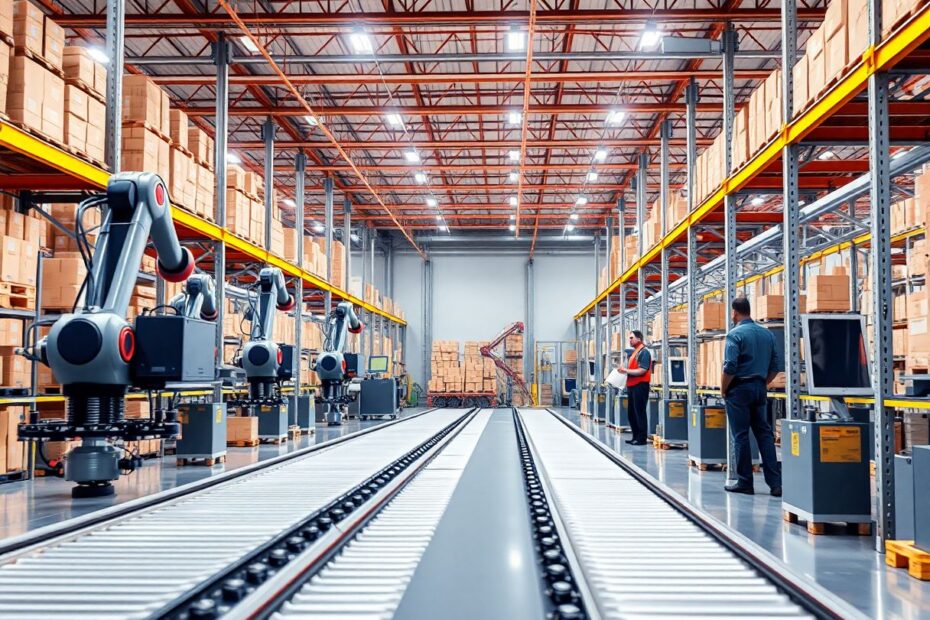

4. Adopt Cutting-Edge Automation Technologies

Invest in robotic picking systems and conveyor automation. Early adopters report 70% faster picking and packing times, according to a study by Deloitte. Key technologies to consider:

- Automated Storage and Retrieval Systems (AS/RS)

- Collaborative robots (cobots) for assisting human workers

- Automated packaging systems

- Autonomous Mobile Robots (AMRs) for material transport

5. Enhance Last-Mile Delivery Options

Partner with local delivery services and implement innovative solutions like drone delivery for urban areas. This can reduce last-mile delivery times by 60%, as demonstrated in pilot programs by companies like UPS and Google. Consider:

- Micro-fulfillment centers in urban areas

- Crowdsourced delivery platforms

- Autonomous vehicle deliveries

- Smart locker systems for 24/7 pickup

6. Implement Real-Time Tracking and Analytics

Provide customers with real-time order tracking and use the data to identify and address bottlenecks in your fulfillment process. According to a survey by Convey, 93% of shoppers want to stay informed throughout the delivery process. Implement:

- GPS tracking for in-transit shipments

- Predictive ETAs based on real-time traffic and weather data

- Automated customer notifications at key stages of the fulfillment process

7. Optimize Your Returns Process

A streamlined returns process can improve customer satisfaction and reduce the overall impact on your OFCT. Aim for a 24-hour turnaround on returns processing. Strategies include:

- Providing easy-to-use return labels with original shipments

- Offering in-store returns for online purchases

- Using AI to quickly assess the condition of returned items and route them appropriately

The Future of Order Fulfillment: Trends to Watch

1. Hyper-Personalized Fulfillment

By 2025, 70% of consumers will expect personalized packaging and delivery options, according to a report by Accenture. Prepare your fulfillment process to accommodate these demands by:

- Implementing on-demand packaging systems that create custom-sized boxes

- Offering personalized inserts or gift wrapping options

- Allowing customers to choose specific delivery time windows

2. Sustainable Fulfillment Practices

Eco-friendly packaging and carbon-neutral shipping options will be standard. Companies leading in sustainable practices see a 20% increase in customer loyalty, as reported by Nielsen. Consider:

- Using biodegradable packaging materials

- Optimizing delivery routes to reduce carbon emissions

- Offering carbon offset options at checkout

3. Augmented Reality in Warehouse Operations

AR-assisted picking could improve accuracy by 99.8% and significantly reduce training time for new warehouse staff, according to a study by DHL. Potential applications include:

- Visual picking guidance overlaid on the warehouse environment

- Real-time inventory information displayed in workers' field of view

- Remote expert assistance for complex tasks

4. Blockchain for Supply Chain Transparency

Implementing blockchain technology in your supply chain can improve traceability and reduce delays caused by documentation errors by 85%, as demonstrated in pilot programs by Walmart and IBM. Benefits include:

- Improved product authenticity verification

- Real-time tracking of shipments across multiple carriers

- Streamlined customs clearance processes

5. AI-Driven Predictive Fulfillment

Advanced AI systems will enable predictive shipping, where products are shipped before orders are placed, based on forecasted demand. Amazon has already patented this technology, which could revolutionize e-commerce by:

- Reducing delivery times to near-zero for common items

- Optimizing inventory distribution across fulfillment networks

- Personalizing product recommendations based on predicted needs

Measuring and Monitoring Your OFCT

To continually improve your OFCT, implement these key performance indicators (KPIs):

- Perfect Order Rate: Aim for 95% or higher

- On-Time Delivery Rate: Target 98% or above

- Order Accuracy Rate: Strive for 99.9%

- Average Fulfillment Cost Per Order: Benchmark against industry standards

- Inventory Turnover Rate: Aim to increase this over time without sacrificing availability

Regularly review these metrics and set aggressive improvement targets. Use advanced analytics tools to identify patterns and predict potential issues before they impact your OFCT.

Conclusion: The Competitive Edge of Efficient Fulfillment

As we move towards 2025 and beyond, mastering your order fulfillment cycle time is no longer just an operational concern—it's a strategic imperative. Companies that excel in this area will see significant gains in customer satisfaction, operational efficiency, and financial performance.

By implementing the strategies outlined in this guide and staying ahead of emerging trends, you can transform your fulfillment process into a powerful competitive advantage. Remember, in the world of e-commerce, the race is often won by those who can get products into customers' hands the fastest and most efficiently.

Invest in your OFCT today, and watch your business thrive in the hyper-competitive marketplace of tomorrow. With a relentless focus on optimization and innovation in your fulfillment processes, you'll be well-positioned to meet and exceed customer expectations, driving growth and success in the dynamic world of e-commerce.